Contract management

Through reliable contract control we are able to reduce end cost.

Through product lifecycle management, we can repair products years after their creation assuring customer satisfaction and avoid unplanned costs.

By using efficient communication method we reduce communication failure resulting in faster work.

From first contact to the supply of spare part our precedent experiences allowed us to master the handling of complex contracts. Those contracts where of course in several different field of work from pneumatic to electronic.

We have created a system that allows us to create a stable and reliable contract management system.

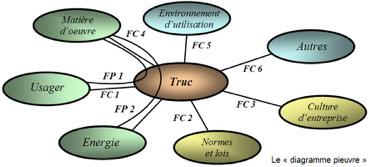

This is of course a way different than simply treating the contract, it’s actually understand how the contract works.

Contract Lifecycle Management (CLM)

Through our capability to repair products 10 years after they reach the market, we assure our customers a safe device that will continue to work years after their purchase. This will also help avoiding unplanned production costs.

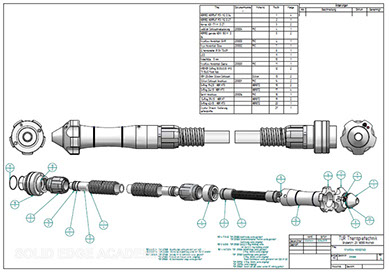

BOM

We are able to give our client the best BOM solution adapted to their situation. Our BOM’s are adapted for the usage in :

- Purchasing

- Production

- Engineering

This work has to be thorough in order to be usable by everyone so we include every single detail of your product into the final version.

Responsive BOM

A BOM is not just a bunch of spread sheet whose sole purpose is to exist.

But in order to do so, the architecture of the BOM must be responsive to the situation in it.

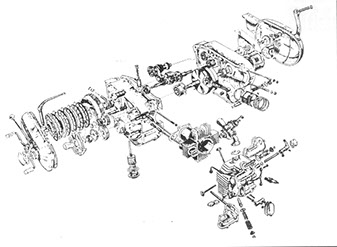

Regardless if the product is simple or complex we create Sub-assemblies adapted for easy usage.

Our precedent realization allows us to create the best architecture adapted for the usage in production, purchase, and engineering.

Since each product isn’t the same and we create interactive and responsive BOM‘s.

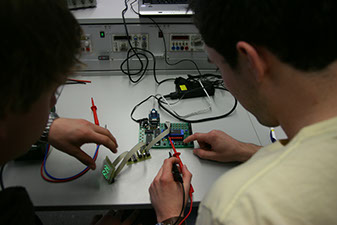

Testing and test realization

Long experience of testing phase allowed use to optimize our testing process resulting in faster testing.

Verification and validation

Through our validation procedure we create a constantly evolving system allowing us to improve the product and the process.

A project doesn’t end once the product is finished and ready to ship. It ends years later once the spare production ends. Our methods allows us to validate a product through careful verification protocols.

Test protocols

Our test protocol are carefully designed in order to reduce failure rate during the warranty period, efficiently reducing customer service cost.

Validation procedures

Through a careful validation procedure we are able to bring forth better quality product and improve our processes. we reduce production cost and through product quality justify our price placement.